IN THE early 1980s Australia’s automotive industry was struggling for survival. Hit by a plummeting Aussie dollar and struggling with the rescue plan devised by then industry minister John Button, glimmers of optimism were everywhere.

In 1985, a Sydney consortium vying for research and development grants under a new federal scheme revealed plans for a home-gown grand tourer wearing Ford Laser tail-lights and Austin Kimberly door handles. This is that story.

“IT HAS to be front engined." Sir Jack Brabham pauses, then drives the point home. "It has to be front-engined because it's going to be a practical car. Practical. For four people and luggage. It couldn't be mid-engined. There isn't one of them I'd buy. They're too cramped, too noisy, too complicated."

That's the Brabham philosophy all over, of course – practical. It's a characteristic that helped make him three times World Champion in Grand Prix racing; and still the only man to win the title driving a Formula One car of his own design and manufacture.

“The art of the practical” was first published in the October 1985 edition of Wheels magazine.

These days that same practical approach is Brabham's stamp on an exciting new venture: an all-Australian Grand Touring car to challenge the world's best. And, no doubt, to beat them if Sir Jack can have his way.

We spoke with him by phone while he was in England during one of his fairly frequent trips overseas. Even at that distance there was no mistaking his enthusiasm for the concept and for the project as he warms to the subject of this promising, practical design.

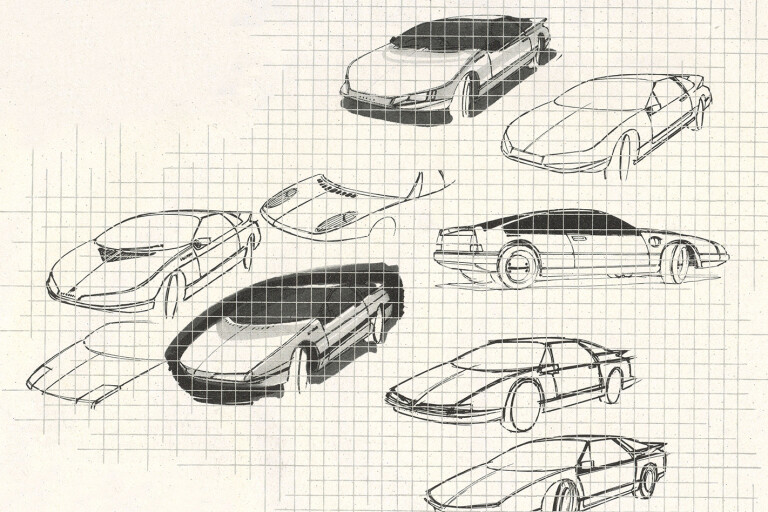

The working brief calls for a high-performance four-seater, a true Grand Touring express. It's to be a straightforward car with conventional layout. That is, front engine and rear drive. While in no way revolutionary the design isn't simplistic either and lends itself to the use of modern materials and techniques throughout. Above all else it's to be a proper car capable of being fully developed as a workable and producible product.

The design – code-named Ozcar – includes a large and healthy engine up front, teamed with either five-speed manual or four-speed overdrive automatic transmission to choice. There'll be power rack and pinion steering, all-independent suspension and four-wheel disc brakes.

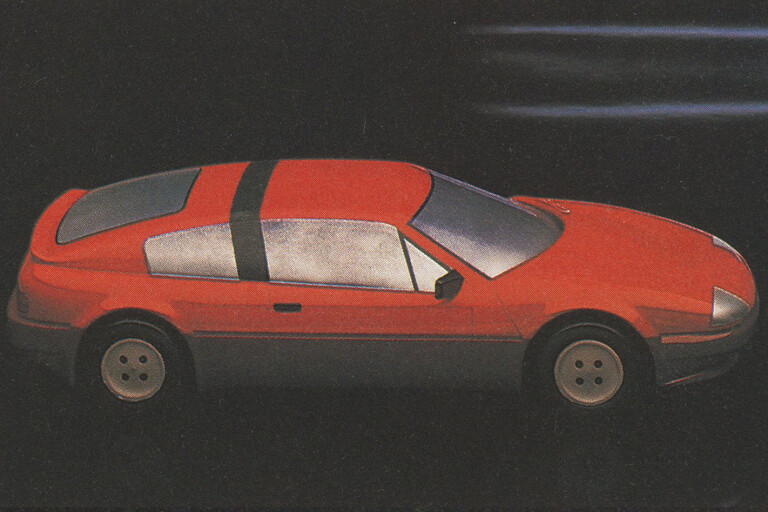

Fabricated from sheet steel, the cabin-capsule chassis is to be clad with bolt-on panels, some of them aluminium pressings, others Kevlar mouldings. The body has two doors and a large rear hatch, plus detachable targa-type roof panel.

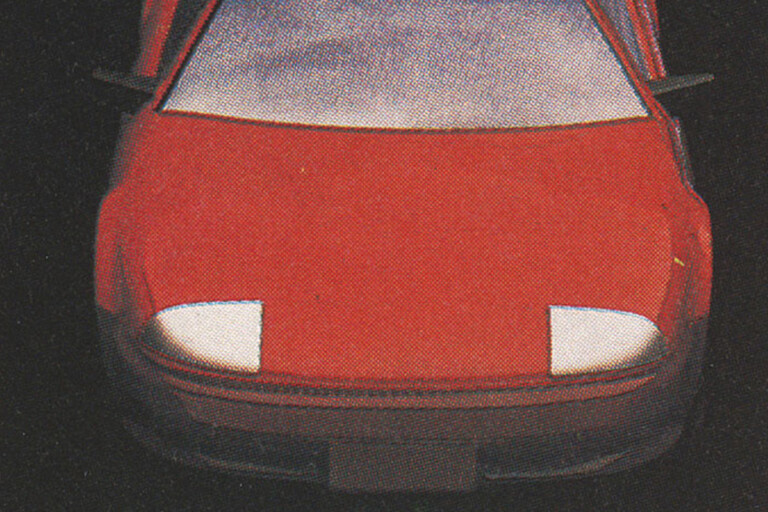

The deep, steeply raked windscreen is sited farther forward than usual to optimise A-pillar placement and maximise effective cabin length, though this means the engine, probably a V8, will fit back into the recessed cowl and firewall. Even so, engine accessibility is not expected to be a problem, because the bonnet and front fenders form a single section above the bumper and side relief line, and tip forward en masse.

Since the deeply recessed firewall leads to a broad centre tunnel which acts as the chassis spine, it might be thought that narrow footwells must result. In fact they'll be more than adequate because the body is fully 1905mm wide. That's almost 50mm wider than the Falcon, over 180mm wider than the Commodore.

Yet with just 1219mm overall height the Ozcar is much lower than the Ford and Holden. And in spite of its reasonably long (2749mm) wheelbase, which falls between that of the two family sedans, the Ozcar's 4673mm overall length is about 40 mm less than the Holden's.

Inside, the cabin will offer first-class accommodation and a host of features, not least the fold-down rear backrest; that practical thinking again. But perhaps the interior's main feature, particularly from the conceptual aspect, is that the facia and instrument pod are designed for easy transpositioning for either left- or right-hand drive. In the same vein the vertical centre console, with its sound system and other secondary controls, pivots to face either the driver or the front-seat passenger.

Touches such as those show that even at this fairly early stage the Ozcar avoids esoteric flights of fancy and instead concentrates on sound, sensible issues. Brabham, involved with the Ozcar concept and general planning from the outset, leaves no doubt that it's developing "… a very practical concept. It's new but quite feasible... the sort of thing that can and should be done in Australia... there wouldn't be any real rivals because this sort of car doesn't exist at present, but there'd be a market for it, not just in Australia. Future exports could be a big part of it."

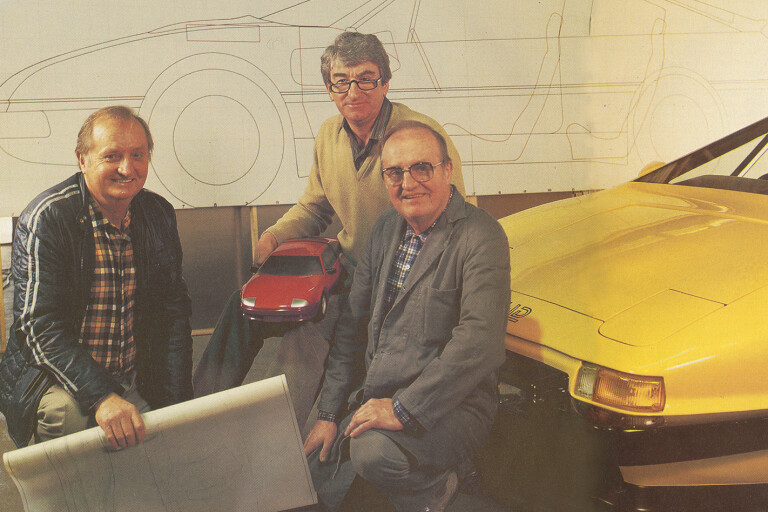

Those sentiments are echoed by others connected with the Ozcar project, at the centre of which is the Sydney-based Hi-Tee Car Co with its three principals: Cliff Trefry and the Hadley brothers, Wally and Bob. If they sound familiar it's because they're the team that built the impressive Triad mid-engined coupe reported in WHEELS, November 1984.

It was through the Triad that Brabham became associated with the Ozcar project. Asked to give an opinion during a Triad test session, Brabham found room for improvement in some of its dynamics but was so impressed by its high quality construction and immaculate finish that when the Ozcar was mooted he agreed to be design/engineering consultant.

Then there's Ken Mathews, the project's marketing man. No stranger to high performance cars and other anti-ordinary models (WHEELS July 1984), Mathews knows better than most that it's one thing to develop a good product, but something else to produce it properly and something else again to sell it.

He runs a very successful Honda/Saab dealership and has previous associations with Lamborghini, de Tomaso and Maserati agencies. Though used to dealing in big numbers, Mathews has lost count of the exotics he has owned. Enough that the list has covered several Lambos up to the Countach, several Ferraris up to the Boxer, and several Porsches up to his current Carrera cabrio.

Besides knowing cars, and what makes good ones and bad ones, Mathews also knows how and where to sell them. He too is convinced of the Ozcar's sales potential; he says there'll always be a demand for a good-looking, good-handling road runner with a fairly big engine in a well-developed chassis. He believes that demand has been left unsatisfied since some makers moved up-market with very exotic mid-engine designs while others switched from amply endowed V8s to smaller turbocharged fours and sixes.

"But really," Mathews says, "you only have to drive a Brock Commodore to realise that the front-engine V8 chassis is alive and well and gives a big kick without compromising practicality. That's why we've gone that way with our design. We've very purposely avoided making it radical or unconventional. But we're very deliberately including proven modern features and top equipment. And we're very conscious of the fact that the project gives a remarkable opportunity for developing and employing the latest technologies."

Shades of the Ilinga you might think, recalling the ill-fated venture that proposed to manufacture an Australian ultimate-GT in the early '70s. But other attempts aren't a factor in Hi-Tee's project. Instead the basis of success is seen in the likes of the Jensen Interceptor, Aston Martin, Iso Rivolta and particularly the Lamborghini Espada, which Mathews holds in high esteem.

"That's pretty much the starting point, the aim: an updated Espada."

If you look at it another way you perhaps see something of the Rover 3500 in the V8 hatchback idea. Brabham quickly dispels any suggestion of such an influence: "No, nothing like the Rover – except for having the engine at the front and a hatch at the tail."

Mathews leaves no doubt that the conventional aspect is as important to the marketing as to the car itself. It means the car is easier to design, easier to develop, easier to produce, easier to service and ultimately easier to sell.

How many could he sell?

"We're talking of a car costing $40,000 in today's money. I'd be looking to sell, say, 20 a year in Australia but many more overseas. There's almost no limit to how many could go overseas with the right kind of marketing. Y'know it takes only five on one market and 10 on another, and 10 on yet another and so on and soon they add up to a few hundred a year. Asia and the Middle East and the US west coast, even California alone, are ripe for this car. Get things rolling and the limit would be not how many we could sell but how many we could make."

So far, of course, the score stands at zero because the project amounts to five men's enthusiasm, a sheaf of drawings, a one-eighth scale conceptual model and a full-scale side elevation cross section drawing. lt's called having-to-start-somewhere, and it's a long way from there to the end of a production line and sales showroom.

How far away is that? "About two million dollars and two years,” says Trefry. Which is why Hi-Tee has applied for a slice of the Motor Vehicle and Components Development Grants Scheme. Announced late in 1984, the Grants Scheme will distribute a maximum of$150 million over the five years to 1988/89.

The financial assistance is intended to "encourage the development of Australian-designed motor vehicles and automotive components”. Eligible applicants will be limited to Australian incorporated companies engaged in (or intending to become engaged in) the manufacture in Australia of vehicles of a kind covered by the Passenger Motor Vehicle Manufacturing Plan, or components for these vehicles or components which could be used in these vehicles.

Contrary to some popular opinion the big companies won't necessarily get all the cream. There's ample scope for small companies' projects which satisfy the Automotive Industry Authority's criteria. Hi-Tee believes its Ozcar project fulfils both letter and spirit of the scheme's objectives.

"Two million sounds a lot, and it is," agrees Trefry. "But that's what we've applied for to do the job properly. Realise that it's not a lump sum in the hand. Whatever grants are given are paid in instalments over so-many years. And the money's taxable, so you might actually get only half what you're granted."

It also has to be realised that grants aren't being allocated for the manufacturing of suitable products; they're intended for research and development. In Hi-Tee's case that means building, testing and developing the Ozcar prototype, getting it from the drawing board to production-ready stage. It would involve setting-up in suitable premises, adding staff, initiating the thousand and one aspects of creating a prototype from the ground up, and all the while keeping future production considerations in mind.

Trefry and Mathews are already quite well versed in that aspect. Between them they've visited every worthwhile low-volume and specialist maker in the UK, including Panther, Lotus, TVR, Auto kraft and Morgan. Mathews also has manufacturing connections in Italy, England and Korea.

At a pinch, he says, some parts could be produced overseas; the Koreans especially are always willing and able to participate. But that's only a last resort because there's unanimously firm resolve to keep the Ozcar virtually all-Australian.

They know that even with a grant behind them the job is far from easy. Otherwise everyone would do it. If Hi-Tec gets only part of the grant applied for, or if its submission is rejected, then the whole thing becomes that much more difficult and slow with the need for private funding and perhaps some compromises. But whatever it takes, the commitment is there.

Though the one-eighth model hasn't been wind-tunnel tested the Ozcar crew is confident that the aerodynamics are essentially sound. The contours have been kept smooth and clean, and the body in plan view follows a good rule by tapering off slightly from front to rear.

The full-size body will enable Hi-Tee to expand its experience with Kevlar and other advanced laminates, and to produce resilient bumper/nose/tail sections. It will also be a medium from which to develop dies for pressing the aluminium panels; not prohibitively expensive steel dies, but affordable special epoxy dies suitable for low-volume production runs.

Other aspects of the design are already firming-up too. "We're hoping to use the five-litre Holden V8 of course," says Mathews. "It's local and strong and even in Brockified form it gives the sort of performance we're after. On the other hand, while it is · good enough to get the prototype going and practical enough to see the car into production, it still leaves plenty of scope for further development."

He leaves our suggestion of fuel injection and single-cam heads hanging. Trefry adds: "Then consider the transmissions. We want the best five-speed available, even if it has to be imported; either a ZF or Getrag unit. The automatic - Jack insists on an automatic, a four-speed it has to be - isn't decided as yet."

There's plenty time enough for that, of course, because the project still has a way to go before the first Ozcar fires in anger. And it would be even further down the road before production could begin, by which time it mightn't be called the Ozcar at all.

"It's not all cut and dried yet of course," says Sir Jack. "But, yes, if things pan out, if everything falls into place as we reckon it should, then this car will be a Brabham."

COMMENTS